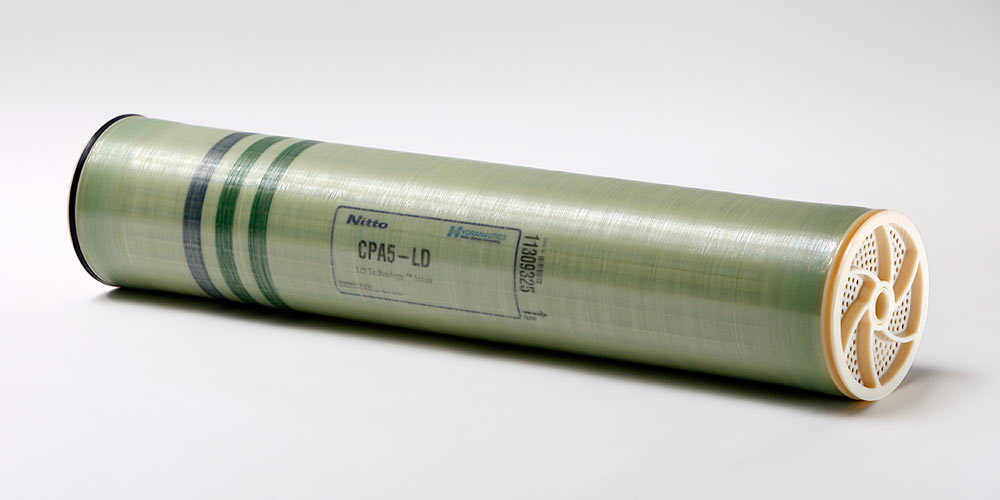

CPA (Composite Polyamide) elements set the standard for RO membrane elements – over 600 million gallons per day of pure water are produced by CPA elements for global municipalities and industries. 4” and 8” configurations available.

CPA5-LD has minimized biofouling, minimized colloidal fouling and enhanced cleanability. When high performance counts, CPA membranes from Hydranautics set the standard for RO membrane elements. CPA membranes provide the highest salt rejection rates available - every element on every order for every customer.

CPA5-LD-4040 Specifications:

- Permeate Flow: 2,100 gpd (7.95 m³/d)

- Salt Rejection: 99.7% (99.5% minimum)

- Configuration: Low Fouling Spiral Wound

- Membrane Polymer: Composite Polyamide

- Membrane Active Area: 80ft2 (7.43m2)

- Feed Spacer: 34mil (0.864mm) with biostatic agent

The stated performance is initial (data taken after 30 minutes of operation), based on the following conditions:

- 1500 PPM NaCl solution

- 225 psi (1.55 MPa) Applied Pressure

- 77°F (25°C) Operating Temperature

- 15% Permeate Recovery

- 6.5 - 7.0 pH Range

Standard Operating Limits:

- Maximum Applied Pressure: 600 psig (4.16 MPa)

- Maximum Chlorine Concentration: < 0.1 PPM

- Maximum Operating Temperature: 113°F (45°C)

- pH Range, Continuous (Cleaning): 2-11 (1-13)

- Maximum Feedwater Turbidity: 1.0 NTU

- Maximum Feedwater SDI (15 mins): 5.0

- Maximum Feed Flow: 16 GPM (3.6 m³/h)

- Minimum Ratio of Concentrate to Permeate Flow for any Element: 5:1

- Maximum Pressure Drop for Each Element: 10 psi

The limitations shown here are for general use. For specific projects, operating at more conservative values may ensure the best performance and longest life of the membrane. See Hydranautics Technical Bulletins for more detail on operation limits, cleaning pH, and cleaning temperatures.

[/custom-features]Ideal Applications Include:

- Desalting of Well Waters – Municipal Drinking Water

- Reducing TDS Prior to Ion Exchange

- Boiler Make-Up Water

- Ultrapure Water for Semi-Conductor Manufacturing

-

VERY FAST DELIVERY, THANKS

Will buy these membranes again!

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS