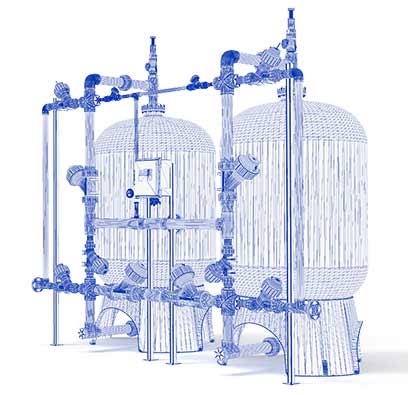

Pure Aqua pressure filters clarify water by removing suspended particles, unpleasant tastes and odors, turbidity, sediment, iron, and unwanted color, all of which are commonly found in surface water. They can be used in a variety of services including: industrial, municipal, and institutional applications.

Filter Media Types

- Activated carbon medium is used to remove taste, odor, organic contaminants, and chlorine as well as being used in many drinking water applications.

- Filter AG is non-hydrous silicon dioxide with many advantages for the reduction of suspended matter.

- Sand is the most common filter media. Generally, fine mesh sand is coupled with a course grain support bed to remove suspended solids and turbidity. Graded in various ranges, Pure Aqua sand can be used as filtration medium or underbedding depending on particle size and application.

- ProSand is based on a rare natural mineral. Its unique properties radically improve the performance and cost of media filtration.

- Gravel has a highly spherical shape that promotes good flow and even distribution in support beds.

- Anthracite is recommended as a filter medium where additional silica in the water is not desirable and can remove lighter weight turbidity. Anthracite is typically used in applications where silica pick-up is undesireable.

- Calcite media is specially graded calcium carbonate compound for neutralizing acid with consistent dissolving rates for water treatment.

- Manganese Greensand media is treated siliceous material for treating water containing iron, manganese and hydrogen sulfide through oxidation.

- Multimedia is required when maximum quality water is required and unwanted sediment is too small to be removed by standard media. It consists of multiple layers of increasing grain size to remove sediment as small as 10 microns.

Advantages of Multimedia Filtration

- Relatively inexpensive, no recurring cost of consumables

- Proven process and most tested forms of water treatment

- Systems are robust with no moving parts inside the tanks

- Modular control valves designed for operational flexibility

- Filtration media is inexpensive and long-lasting

- Easily cleaned and maintained

- Resistant to fouling (clogging)

Multimedia Filtration Operating Cycles

Service Cycle

Water flows downward through the media while solids accumulate in the media bed. The purified water passes through to downstream processes.

Backwash Cycle

When the filter begins to clog or when the head loss (pressure drop) through the bed increases, flow rates are reduced. To prevent degradation of water quality, the flow is reversed. This is directed by the control valve(s) to drain, carrying with it, the particulate matter that has built up during service. The required flow is specific to the media and is essential to proper cleaning of the media bed. For media filters, the backwash flow is always higher than the service flow rate.

|

Operation Specifications: |

||

|

|

|

|

Model # |

Average |

Peak |

Backwash |

Tank Size D”xH” |

Media Qty (ft3) |

Pipe Size |

Approx. Weight (lbs) |

|||||

|

GPM |

M3/H |

GPM |

M3/H |

GPM |

M3/H |

|||||||

|

Multi Layers Filters: Anthracite, Sand and Gravel (Turbidity Removal) |

||||||||||||

|

CVP1435MM |

10.7 |

2.4 |

16.1 |

3.6 |

16.1 |

3.6 |

14x65 |

3 |

2" |

302 |

||

|

CVP1645MM |

13.9 |

3.2 |

20.9 |

4.7 |

20.9 |

4.7 |

16x65 |

4 |

2" |

398 |

||

|

CVP1855MM |

17.7 |

4.0 |

26.6 |

6.0 |

26.6 |

6.0 |

18x65 |

5 |

2" |

521 |

||

|

CVP2160MM |

24.1 |

5.5 |

36.2 |

8.2 |

36.2 |

8.2 |

21x62 |

6.5 |

2" |

727 |

||

|

CVP24100MM |

31.4 |

7.1 |

47.1 |

10.7 |

47.1 |

10.7 |

24x72 |

8.5 |

2" |

965 |

||

|

CVP30150MM |

49.1 |

11.2 |

73.7 |

16.7 |

73.7 |

16.7 |

30x72 |

13 |

2" |

1565 |

||

|

CVP36210MM |

70.7 |

16.1 |

116.2 |

26.4 |

102.0 |

23.2 |

36x72 |

19 |

2" |

2199 |

||

|

Model # |

Average |

Peak |

Backwash |

Tank Size D”xH” |

Media Qty (ft3) |

Pipe Size |

Approx. Weight (lbs) |

|||||

|

GPM |

M3/H |

GPM |

M3/H |

GPM |

M3/H |

|||||||

|

AG Filters: Non Hydrous Silicon Dioxide (Turbidity Removal) |

||||||||||||

|

CVP1435AG |

7.5 |

1.7 |

12.8 |

2.9 |

10.7 |

2.4 |

14x65 |

8.53 |

2" |

151 |

||

|

CVP1645AG |

9.7 |

2.2 |

16.7 |

3.8 |

13.9 |

3.2 |

16x65 |

4 |

2" |

190 |

||

|

CVP1855AG |

12.4 |

2.8 |

21.2 |

4.8 |

17.7 |

4.0 |

18x65 |

5 |

2" |

228 |

||

|

CVP2160AG |

16.9 |

3.8 |

28.9 |

6.6 |

24.1 |

5.5 |

21x62 |

6.5 |

2" |

317 |

||

|

CVP24100AG |

22.0 |

5.0 |

37.7 |

8.6 |

31.4 |

7.1 |

24x72 |

8.5 |

2" |

418 |

||

|

CVP30150AG |

34.4 |

7.8 |

58.9 |

13.4 |

49.1 |

11.2 |

30x72 |

13 |

2" |

711 |

||

|

CVP36210AG |

49.5 |

11.2 |

84.8 |

19.3 |

70.7 |

16.1 |

36x72 |

19 |

2" |

1012 |

||

|

Activated Carbon Filters: Granular Form with High Degree of Porosity (Taste, Odor and Color Removal) |

||||||||||||

|

CVP1435AC |

7.5 |

1.7 |

12.8 |

2.9 |

12.8 |

2.9 |

14x65 |

3 |

2" |

159 |

||

|

CVP1645AC |

9.7 |

2.2 |

16.7 |

3.8 |

16.7 |

3.8 |

16x65 |

4 |

2" |

200 |

||

|

CVP1855AC |

12.4 |

2.8 |

21.2 |

4.8 |

21.2 |

4.8 |

18x65 |

5 |

2" |

241 |

||

|

CVP2160AC |

16.9 |

3.8 |

28.9 |

6.6 |

28.9 |

6.6 |

21x62 |

6.5 |

2" |

424 |

||

|

CVP24100AC |

22.0 |

5.0 |

37.7 |

8.6 |

37.7 |

8.6 |

24x72 |

8.5 |

2" |

589 |

||

|

CVP30150AC |

34.4 |

7.8 |

58.9 |

13.4 |

58.9 |

13.4 |

30x72 |

13 |

2" |

983 |

||

|

CVP36210AC |

49.5 |

11.2 |

84.8 |

19.3 |

84.8 |

19.3 |

36x72 |

19 |

2" |

1350 |

||

|

Birm Filters: Insoluble Catalyst (Fe and Mn Reduction) |

||||||||||||

|

CVP1435BM |

7.5 |

1.7 |

12.8 |

2.9 |

12.8 |

2.9 |

14x65 |

3 |

2" |

208 |

||

|

CVP1645BM |

9.7 |

2.2 |

16.7 |

3.8 |

16.7 |

3.8 |

16x65 |

4 |

2" |

266 |

||

|

CVP1855BM |

12.4 |

2.8 |

21.2 |

4.8 |

21.2 |

4.8 |

18x65 |

5 |

2" |

323 |

||

|

CVP2160BM |

16.9 |

3.8 |

28.9 |

6.6 |

28.9 |

6.6 |

21x62 |

6.5 |

2" |

531 |

||

|

CVP24100BM |

22.0 |

5.0 |

37.7 |

8.6 |

37.7 |

8.6 |

24x72 |

8.5 |

2" |

729 |

||

|

CVP30150BM |

34.4 |

7.8 |

58.9 |

13.4 |

58.9 |

13.4 |

30x72 |

13 |

2" |

1197 |

||

|

CVP36210BM |

49.5 |

11.2 |

84.8 |

19.3 |

84.8 |

19.3 |

36x72 |

19 |

2" |

1663 |

||

|

Calcite Filters: |

||||||||||||

|

CVP1435CF |

7.5 |

1.7 |

12.8 |

2.9 |

12.8 |

2.9 |

14x65 |

3 |

2" |

376 |

||

|

CVP1645CF |

9.7 |

2.2 |

16.7 |

3.8 |

16.7 |

3.8 |

16x65 |

4 |

2" |

490 |

||

|

CVP1855CF |

12.4 |

2.8 |

21.2 |

4.8 |

21.2 |

4.8 |

18x65 |

5 |

2" |

603 |

||

|

CVP2160CF |

16.9 |

3.8 |

28.9 |

6.6 |

28.9 |

6.6 |

21x62 |

6.5 |

2" |

895 |

||

|

CVP24100CF |

22.0 |

5.0 |

37.7 |

8.6 |

37.7 |

8.6 |

24x72 |

8.5 |

2" |

1205 |

||

|

CVP30150CF |

34.4 |

7.8 |

58.9 |

13.4 |

58.9 |

13.4 |

30x72 |

13 |

2" |

1925 |

||

|

CVP36210CF |

49.5 |

11.2 |

84.8 |

19.3 |

84.8 |

19.3 |

36x72 |

19 |

2" |

2727 |

||

|

Standard Features: |

Available Options: |

|

|

|

The ideal applications of a Media Filter include: |

||

|

|

|

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

Everything about these filters is exceptional.

I have been dealing with Pure Aqua for over 10 years and they have proved to be very reliable with excellent products that always helped us in our projects. Thank you Pure Aqua and all the best.

-

Engineers at Pure Aqua are knowledgeable & provide great customer service

I have used the MF-500 filter to remove organic and remove odor from water. I am very satisfied in using this product!

-

Great Industrial Water Media Filter. First-rate!

For my NSF certification this product has been doing good. No rejection for water quality.

- 360view:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/content/360Views/MF-500.0.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS