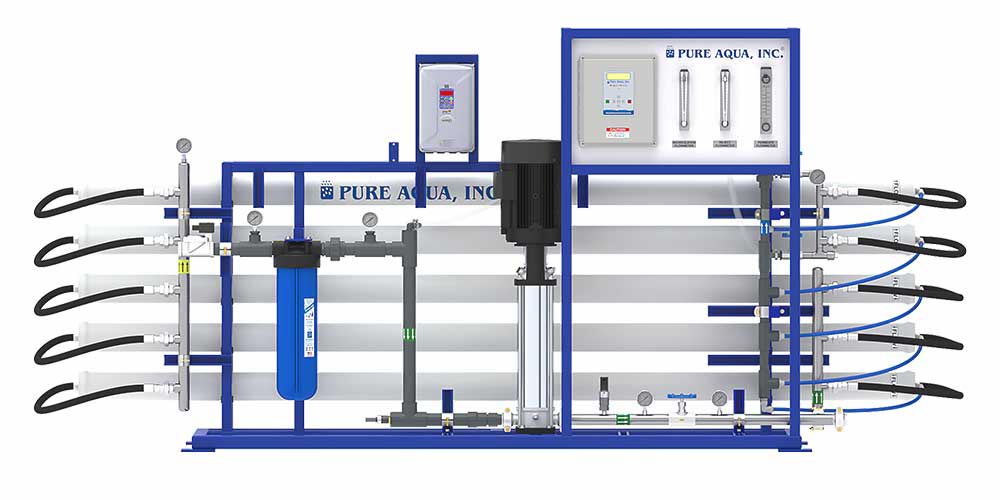

Pure Aqua supplies a full line of standard and fully customizable brackish reverse osmosis systems, all of which are engineered using advanced 3D computer modeling and process design software for accurate and customized solutions.

Regardless of the condition of your water supply, brackish type water is more difficult to treat due to the increased probability for changes in salinity over time. This occurrence ultimately affects water prices since energy usage is elevated and the treatment process is burdened as a result of an upward movement of salinity throughout the groundwater.

A significant aspect for the effective running of a brackish reverse osmosis system is the RO feedwater quality, which becomes resolved by the consistency of the water body and the success of the pretreatment process.

Customizable & High Capacity

Pure Aqua engineers have designed a second line of commercial reverse osmosis systems. This line, RO-300 Series, features systems that are able to purify higher capacities of water and are therefore made with higher quality materials. These brackish RO systems ideally treat tap/brackish water for the application of drinking water or other commercial uses that require ultra-purified water.

Compared to the RO-200 Series, RO-300 Series is displayed vertically and made with heavy-duty materials to withstand the higher capacity that it produces. For example, stainless steel piping is used in RO-300 brackish reverse osmosis system. Whereas, the RO-200 uses standard tubing. The high pressure pump is 316L stainless steel. Each pressure vessel has multi membrane, and the vessels are installed horizontally.

Ultra-high-quality water for specific applications and is customizable depending on the application and source of the water. Pure Aqua, Inc. takes pride in their ability to offer the most appropriate solution for any water treatment need.

Brackish Reverse Osmosis Process

Brackish RO systems require pre-treatment of which is always included in the sale unless the water is already being treated. Pre-treatment systems depend on the quality of water that is treated along with the application. Taking those two into account is how our engineers recommend the most appropriate pre/post treatment for the system. Components of pre/post treatment include multimedia and activated carbon filters along with water softeners and UV sterilizers. A chemical dosing system and/or a cleaning skid are also incorporated into the system.

Brackish reverse osmosis systems are equipped to purify water from rivers, lakes, wells, and the sea. With high pressure pumps, water is pressurized to pass through a finely pored semi-permeable membrane and filter the water. Around 99% of contaminants including salts, bacteria, and other particles are removed leaving the water in its most purified form. The system releases the purified (permeate) water from one stream and the reject filled with concentrated contaminants from another. Depending on the application of the water, post-treatment may be applied.

High Capacity of BWRO Systems

The RO-300 series comes with many similar standard features as the RO-200 series. However, the capacity of RO-300 is a main differentiator between the two. RO-300 series is comprised of brackish reverse osmosis systems that can accommodate between 13,000 to 32,000 GPD with feed water TDS of 1000 ppm to 5000 ppm.

Pure Aqua’s RO systems are capable of removing salts as well as other impurities such as bacteria, sugars, proteins, dyes and constituents having a molecular weight greater than 150-250 Dalton. In addition, these RO systems have the ability to remove color, iron, odor, hardness, sulfur, and chlorine while being economical and efficient through the usage of Dow Filmtec, Hydranautics, and Toray membranes (Our systems are made in the USA).

Buying Guide

Choosing the correct RO-300 model is simple. The following information must be provided:

The following information is requested to recommend the most appropriate system:

To find the most appropriate system for your use, please have the following information ready:

- Flow rate (GPD, m3/day, etc.)

- Feed water TDS and water analysis: this information is important to prevent membranes from fouling, as well as help us choose the correct pre-treatment.

- Iron and manganese must be removed before the water enters reverse osmosis unit

- TSS must be removed before commercial RO system

- SDI must be less than 3

- Water should be free from oil and grease

- Chlorine must be removed

- Available voltage, phase, and frequency

- Dimensions of proposed area where commercial RO system will be installed

Additional Features:

The cost of a system varies depending on which and how many pre/post treatments are needed to adequately treat the water and/or for the intended application.

The following are all the possible additional treatments to a reverse osmosis system that will ensure longevity and optimal purification:

- Prechlorination dosing

- Media filter

- Carbon filter

- Water softener

- Antiscalant dosing

- NSF components

- Advanced controller

- Advanced instruments

- Iron removal filter

- High TDS application

- Skid mounted system

- Calcite filter

- Blending systems

- Three phase system

- Variable frequency drive VFD

|

Operation Specifications |

||

|

|

|

| Commercial Brackish Water Reverse Osmosis Systems RO-300 |

|||||||

|---|---|---|---|---|---|---|---|

|

Model Number |

Permeate Flow Rate |

Quantity of 4" Membranes |

Motor Rating at 1,000 ppm |

Approx. Weight (lbs) |

Dimensions L" x W" H" |

||

|

GPD |

M3/D |

60Hz (hp) |

50Hz (kw) |

||||

| TW-13K-3340 | 13,000 | 49 | 9 | 2 | 2 | 750 | 141x35x66 |

| TW-15K-5240 | 15,000 | 57 | 10 | 3 | 3 | 850 | 109x35x66 |

| TW-18K-4340 | 18,000 | 68 | 12 | 5 | 3 | 875 | 151x35x66 |

| TW-22K-5340 | 22,000 | 83 | 15 | 5 | 3 | 900 | 142x35x66 |

| TW-24K-8240 | 24,000 | 91 | 16 | 5 | 4 | 950 | 113x35x71 |

| TW-27K-6340 | 27,000 | 102 | 18 | 5 | 4 | 990 | 152x35x66 |

| TW-32K-7340 | 32,000 | 121 | 21 | 5 | 4 | 1,025 | 144x35x64 |

|

For more information, please view/download our "Data Sheet" |

|||||||

Note: If the feed water TDS exceeds 1,000 ppm, the system model number changes to BW-XXK-XXXX, and a suffix is added to the end of the model number: “-3” is added if the TDS is 3,000 ppm or less, and “-5” is added if the TDS is 5,000 ppm or less. Example: Required system to produce 27,000 GPD with a feed water TDS of 5,000 ppm, the corresponding model number is: “BW-27K-6340-5”.

| Standard Features: | Available Options: |

|---|---|

|

|

| The ideal applications for brackish reverse osmosis systems include: | ||

|

|

|

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

We are now a happy user of their TW-18K-5340.

We needed to polish the city supplied water with RO to have a water required for beverage product. We provided specs to Pure Aqua and they came back with design and pricing. We are now a happy user of their TW-18K-5340.

-

Quality of water is what we were expecting

Pure Aqua has good price and great understanding on water filtration systems. We purchased the BW-24K-8240 and its price overall beat the competition and quality of water is what we were expecting.

-

Awesome Engineering there!!

High TDS water is our plant's issue so we contacted Pure Aqua for recommendation. We needed a system to produce 30,000 GPD and they provided us the system. Now the plant is being supplied with low TDS water for process.

-

We don't expect equipment scaling anymore

We have a process machine that is always being de-scaled due to bad water. We asked Pure Aqua for design and pricing and bought their BW-27K-6340. Water quality conforms to equipment requirement now so we don't expect equipment scaling anymore.

-

Higher system recovery.

Our facility bought a BW-32K-7340 to recover more water from a RO primary system. Pure Aqua's customized design gave us flexibility to a higher system recovery. Glad we chose them.

-

Great system. Simple to operate

Great system. I have one which produces 15 GPM and very simple to operate.

-

Very satisfied.

Found this company in the web and inquired for an RO system. Fast forward 3 months after I am using their BW-18K-4340 for my ranch and system works well. Very satisfied.

-

it‘s working great

Our small farm needs a secondary water supply during summer and we decided to buy from Pure Aqua a High Brackish RO system complete with pre-treatment. We chose BW-27K-6340 and it‘s working great.

-

We are glad we chose Pure Aqua

Started a water bottling business and we are glad we chose Pure Aqua and purchased the TW-22K-5340. We'll recommend them to anybody who needs RO system.

- 360view:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/content/360Views/RO-300-32K-7340.2.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS