Ion Exchange can be defined as a reversible exchange of ions between a solid (resin) and a liquid containing dissolved ions. Mineral salts are comprised of cations and anions. Since deionization requires the removal of all ions, both the negatively charged anions and positively charged cations, minerals capable of attracting both are required. These materials are known as anion and cation exchange resins.

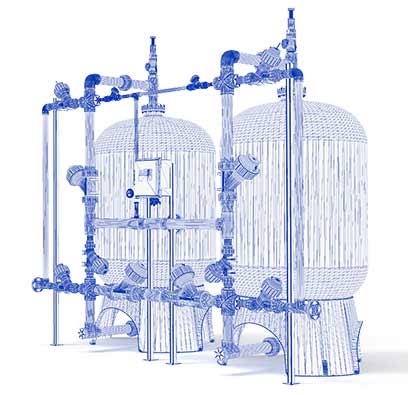

Mixed bed deionizers are fixed bed systems in which ion exchange resins are contained in pressure vessels. The water is then forced through the resin. After a service run, the resin becomes exhausted and unable to remove additional ions so it must be regenerated with strong acid and base solutions to restore its ion exchange capacity..

How Does Mixed Bed Resin Work

Water treatment operators prefer to utilize mixed bed deionization resins in order to refine product water and obtain demineralized water quality. Mixed bed is made up of durable acid cation exchange and strong base anion exchange resin.

More contaminants are exchanged by hydrogen and hydroxyl ions within this process, and the water generated is often exceptionally pure.

|

Model # |

Nominal Capacity |

Service Flow Rate (GPM) |

Pipe Size |

Mineral Tank Size |

Resin Qty. |

Shipping Weight (lbs) |

||

|---|---|---|---|---|---|---|---|---|

|

Average |

Peak |

Cation |

Anion |

|||||

|

MB20-PVN/m9060 |

82,000 |

22 |

33 |

2" |

20"x108" |

3.3 |

4 |

1,300 |

|

MB24-PVN/M9065 |

112,000 |

31 |

47 |

2" |

24"x108" |

4.5 |

5.5 |

1,700 |

|

MB30-PVN/m9070 |

170,000 |

50 |

75 |

2" |

30"x108" |

7 |

8.5 |

2,300 |

|

MB36-PVN/M9075 |

250,000 |

70 |

105 |

2" |

36"x108" |

10 |

12.25 |

3,300 |

|

MB42-PVN/M9080 |

350,000 |

100 |

145 |

3" |

42"x108" |

14 |

17.25 |

4,400 |

|

MB48-PVN/M9085 |

450,000 |

125 |

190 |

3" |

48"x108" |

18 |

22.25 |

5,800 |

|

For more information, please view/download our "Data Sheet" |

||||||||

|

Standard Features: |

Available Options: |

|

|

|

Pure Aqua Deionizers are often used in applications requiring very high water quality, usually as polishers after reverse osmosis. Many industries use DI systems: |

|||

|

|

|

|

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

Great material

Gets the job done in removing harmful contaminants from feed water. It produces highly purified water.

-

Service was exceptional

Produces extremely pure water. Saves business costs due to not requiring chemicals. Excellent product!

-

Best price

shipped same day...fast delivery, thanks

- 360view:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/content/360Views/MB20.283.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS