Reverse Osmosis (RO) systems are known for their ability to purify water and reduce 99% of contaminants. This RO series specializes in industrial grade systems for brackish, surface, and municipal water treatment. With upgraded industrial quality materials and high capacity technology, these industrial BWRO systems are engineered to purify elevated levels of water for almost every industry. Our systems are uniquely designed and engineered in the United States. Our industrial BWRO systems have been strategically designed to be energy efficient and environmentally friendly while producing some of the most high-quality water.

- Compact Design

Our largest tap and brackish water units, the RO-500 Series, comes with a standard pre-treatment consisting of media pre-filters, chemical dosing, and antiscalant. These systems are often customized to fulfill the requirements of specific industrial applications. For this reason, we offer the option to customize the pre-treatment system for certain conditions. Our systems are considered to be one of the most compact industrial reverse osmosis systems in the market with features including state of the art energy saving membranes, robust construction, automatic design, environmentally conservative operations, and long-term reliability.

Economical and efficient, the RO-500 industrial equipment incorporates the latest in RO technology to remove dissolved minerals, particles, organics, solids and other contaminants from the water. The systems use RO membranes as its core separation technology to reject majority of these contaminants. Pure Aqua, Inc. uses the most reputable membrane manufacturers like Dow Filmtec, Hydranautics, and Toray to supply high quality products.

- Containerized Systems

- High Capacity

- Systemic Process

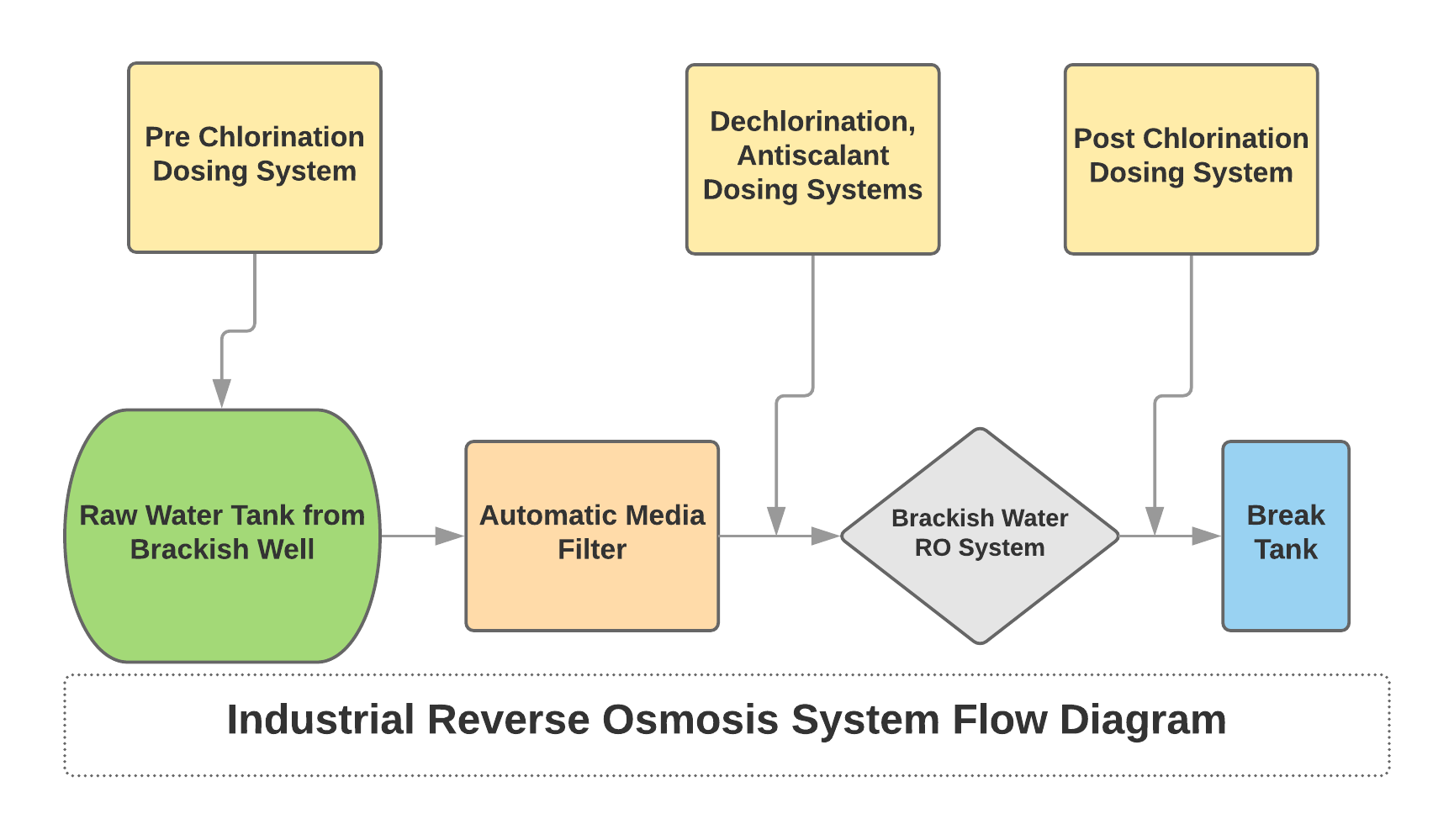

As the feed water enters the system, the first step of the pre-treatment is the pre-chlorination dosing which is injected into the feed stream. This feed stream is headed to a media filter which is the second component of the pre-treatment process to filter out contaminants larger than 10 microns. Next, the water is injected with antiscalant chemicals to reduce hardness of the water and prevent the RO membranes from fouling. The pre-treated water is then pressurized through the RO membranes to produce ultimately purified water and a reject stream of concentrated contaminants. Generally, industrial applications do not require water to be disinfected. However, depending on the application, a disinfection method can be used by means of Post-Chlorination Dosing or a UV Sterilizer.

A diagram of RO system process is shown below.

Industrial Brackish Water Reverse Osmosis System Diagram

- Buying Guide

In order to choose the most appropriate RO system, the following information must be provided:

- Flow rate (GPD, m3/day, etc.)

- Feed water TDS and water analysis: this information is important to prevent membranes from fouling, as well as help us choose the correct pre-treatment.

- Iron and manganese must be removed before the water enters the reverse osmosis unit

- TSS must be removed before entering RO system

- SDI must be less than 3

- Water should be free from oil and grease

- Chlorine must be removed

- Available voltage, phase, and frequency (208, 460, 380, 415V)

- Dimensions of projected area where Industrial RO System will be installed

|

Operation Specifications: |

||

|

|

|

|

Industrial Brackish Water Reverse Osmosis Systems RO-500 |

|||||||

|

Model Number |

Permeate Flow Rate |

Quantity of 8" Membranes |

Motor HP Rating at 1,000 ppm |

Approx. Weight (lbs) |

Dimensions L" x W" x H" |

||

|

GPD |

M3/D |

60Hz |

50Hz |

||||

|

TW-200K-4780 |

200,000 |

757 |

28 |

25 |

30 |

4,700 |

340x45x85 |

|

TW-225K-5680 |

225,000 |

852 |

30 |

30 |

30 |

4,850 |

275x45x80 |

|

TW-270K-6680 |

270,000 |

1,022 |

36 |

30 |

40 |

5,050 |

275x65x80 |

|

TW-320K-7680 |

320,000 |

1,211 |

42 |

40 |

40 |

5,200 |

275x65x80 |

|

TW-360K-8680 |

360,000 |

1,363 |

48 |

40 |

50 |

5,750 |

275x75x80 |

|

TW-410K-9680 |

410,000 |

1,552 |

54 |

40 |

50 |

6,250 |

275x75x80 |

|

TW-450K-10680 |

450,000 |

1,703 |

60 |

50 |

60 |

7,500 |

275x75x80 |

|

TW-500K-11680 |

500,000 |

1,893 |

66 |

60 |

60 |

8,500 |

275x75x80 |

|

TW-550K-11780 |

550,000 |

2,083 |

77 |

60 |

60 |

8,750 |

310x85x100 |

|

TW-600K-13780 |

600,000 |

2,271 |

91 |

75 |

75 |

9,250 |

310x85x100 |

|

TW-700K-14780 |

700,000 |

2,650 |

98 |

100 |

100 |

9,650 |

310x85x100 |

|

TW-800K-16780 |

800,000 |

3,028 |

112 |

80 |

150 |

10,200 |

310x85x100 |

|

TW-900K-18780 |

900,000 |

3,407 |

126 |

100 |

150 |

10,650 |

310x85x100 |

|

For more information, please view/download our "Data Sheet" |

|||||||

Note: If the feed water TDS exceeds 1,000 ppm, the system model number changes to BW-XXXK-XXXX, and a suffix is added to the end of the model number: “-3” is added if the TDS is 3,000 ppm or less, and “-5” is added if the TDS is 5,000 ppm or less. Example: Required system to produce 320,000 GPD with a feed water TDS of 5,000 ppm, the corresponding model number is: “BW-320K-7680-5”.

[/custom-specifications]

|

Standard Features: |

Available Options: |

|---|---|

|

|

[/custom-features]

|

The ideal applications for industrial RO water filtration plant include: |

||

|---|---|---|

|

|

|

[custom-documents]

Industrial Brackish Water Reverse Osmosis BWRO Systems Diagram

[/custom-documents]

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

RO system

Terrific!

- 360view:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/content/360Views/RO-500_270K-6680.2.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH

ENGLISH

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS