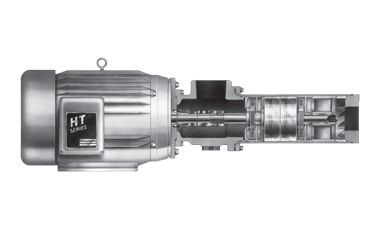

The Webtrol HT Series is the original HeavyDuty Booster Pump, designed for high flow athigh head. The HT Series Booster Pumps arebuilt to withstand the rigorous demands generatedthrough use in the Reverse Osmosis,Deionization, Car wash, Washdown and BoosterLift Station applications, as well as various otherIndustrial and Agricultural uses.

The design of the Webtrol HT Series BoosterPumps are virtually maintenance free in comparisonto pumps that utilize bearing housings thatrequire oil baths to operate. Ease of installationdependability, performance and reliability are justa few of the reasons you should look at theWebtrol HT Series Booster Pumps.Every Webtrol Booster Pump is hand assembledand checked during each step of the assemblyprocess up to the final test where each pump ischecked for flow, pressure, power consumption,leaks, vibration and noise.

[custom-specifications]

| 1 Cast Iron 3PH TEFC Model No. | HP | Dimensions (inches) | Aprox. Wt. (lbs) | ||||||||

| A | B | C | D | E | F | G | H | K | |||

| H60B5-3PHT | 5 | 20.80 | 12.97 | 3.50 | 5.50 | 10.34 | 6.43 | 3.75 | 4.50 | 0.41 | 132 |

| H60B8-3PHT | 7 1/2 | 26.20 | 18.84 | 3.50 | 5.50 | 10.34 | 6.43 | 3.75 | 4.50 | 0.41 | 149 |

| H60B12-3PHT | 10 | 32.60 | 15.47 | 4.50 | 7.00 | 11.12 | 6.43 | 4.25 | 5.25 | 0.41 | 204 |

| H60B15-3PHT | 15 | 40.00 | 20.05 | 4.25 | 8.25 | 14.94 | 10.00 | 5.00 | 6.25 | 0.53 | 250 |

| H60B17-3PHT | 15 | 43.20 | 20.05 | 4.25 | 8.25 | 14.94 | 10.00 | 5.00 | 6.25 | 0.53 | 258 |

| H60B20-3PHT | 20 | 48.10 | 20.05 | 4.25 | 8.25 | 14.94 | 10.00 | 5.00 | 6.25 | 0.53 | 295 |

| H60B23-3PHT | 20 | 52.90 | 20.05 | 4.25 | 8.25 | 14.94 | 10.00 | 5.00 | 6.25 | 0.53 | 306 |

| H60B27-3PHT | 25 | 62.00 | 23.25 | 4.75 | 9.50 | 16.35 | 12.09 | 6.38 | 7.00 | 0.53 | 357 |

| H60B31-3PHT | 30 | 64.40 | 24.17 | 4.75 | 9.50 | 16.93 | 12.20 | 5.50 | 7.00 | 0.53 | 408 |

| H60B34-3PHT | 30 | 72.80 | 24.17 | 4.75 | 9.50 | 16.93 | 12.20 | 5.50 | 7.00 | 0.53 | 420 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| H80B4-3PHT | 5 | 19.70 | 12.97 | 3.50 | 5.50 | 10.34 | 6.43 | 3.75 | 4.50 | 0.41 | 141 |

| H80B6-3PHT | 7 1/2 | 23.70 | 18.84 | 3.50 | 5.50 | 10.34 | 6.43 | 3.75 | 4.50 | 0.41 | 151 |

| H80B9-3PHT | 10 | 28.90 | 15.47 | 4.50 | 7.00 | 11.12 | 6.43 | 4.25 | 5.25 | 0.41 | 188 |

| H80B13-3PHT | 15 | 38.00 | 20.05 | 4.25 | 8.25 | 14.94 | 10.00 | 5.00 | 6.25 | 0.53 | 238 |

| H80B17-3PHT | 20 | 45.40 | 20.05 | 4.25 | 8.25 | 14.94 | 10.00 | 5.00 | 6.25 | 0.53 | 278 |

| H80B21-3PHT | 25 | 52.40 | 23.25 | 4.75 | 9.50 | 16.35 | 12.09 | 6.38 | 7.00 | 0.53 | 329 |

| H80B26-3PHT | 30 | 63.70 | 24.17 | 4.75 | 9.50 | 16.93 | 12.20 | 5.50 | 7.00 | 0.53 | 388 |

| H80B30-3PHT | 40 | 70.70 | 24.37 | 5.25 | 10.50 | 18.16 | 13.74 | 6.25 | 8.00 | 0.66 | 495 |

| H80B34-3PHT | 40 | 77.60 | 24.37 | 5.25 | 10.50 | 18.16 | 13.74 | 6.25 | 8.00 | 0.66 | 515 |

[custom-features]

- Available in both Stainless Steel and CastIron fitted models.

- Heavy duty 7/8” diameter stainless steelshaft with a double keyway.

- High strength, glass filled Noryl impellers precision machined for dimensional stability andefficiency.

- Mechanical seals are stainless steel constructed with Buna N elastomers on cast iron models andViton elastomers onstainless steel models.

Construction and Design Features

-

Closed coupled pump motor with a “C” face, 3450 RPM, 50 or 60 cycle, and a type JM mounting. Oversize ballbearings, class F insulation, and an external slinger ensure trouble free service. The direct coupling of the motorto the pump eliminates the need for a flexible coupling, guard, bearings, lubricator, oil seals, intermediate shaft,and bed plate. You won’t need to deal with troublesome field motor alignment, or noise, vibration, and eventualbearing or coupling failure caused by a misaligned motor.

-

Inlet/motor bracket is a heavy walled casting machined for perfect concentric and perpendicular alignment of themotor shaft with the pump shaft coupling. Inlet size is 3” female NPT.

-

Thick-walled stainless steel pump housing is flared at one end to accept the inlet and welded at the discharge.Flaring allows the tube to be removed easily, unlike threaded pump housing which can be difficult if not impossibleto remove because of galling.

-

The rotating assembly is comprised of the pump shaft and coupling assembly, bottom plate, impellers, diffusers,intermediate diffusers, intermediate and top sleeves and diffuser bearings. It is easily removed by loosening thesets screws in the coupling, unbolting the tube from the inlet, sliding the pump housing over the rotating assembly,and pulling the rotating assembly away from the inlet. The mechanical seal remains in place and undisturbed.

-

Positive sealing “Buna N” o-ring is used to seal off the inlet / motor bracket on cast iron models. A “Viton” o-ringis used on stainless steel models.

-

Welding the discharge to the pump housing makes mechanical seal replacement easy. It eliminates the need tounbolt or unscrew the discharge from the pump housing. A rabbet fit ensures that the diffusers are perfectlyaligned when they are compressed within the pump housing. The discharge thread size is 1 1/2” female NPT.

-

Top shaft sleeve and bearing 316SS shaft sleeve is water lubricated and runs in a “rulon” or bronze bearing thatis molded into the top diffuser, then machined to close concentricity and bore tolerances. Longer pumps use severalintermediate bearings to reduce shaft deflection, vibration, and stress.

-

Impeller wear rings are insert molded into each diffuser at both the suction and discharge side to eliminate plasticon plastic contact and maintain tight clearances for low leakage and high efficiency.

-

Diffuser assemblies, molded of noryl thermoplastic, are concentrically aligned together with rabbet fits and arecompressed inside the pump housing to prevent interstage leakage and pressure loss.

-

Centrifugal impellers are noryl thermoplastic with keyed hubs, and generate pulse-free pressure at high efficiencies.All impellers and diffusers are injection molded at Weber Industries to insure control of dimensional accuracyand material specifications.

-

Oversized stainless steel pump shaft is supported by many intermediate bearings to minimize deflection, vibrationand bending stresses. This combined with the elimination of any stress-rising, sharp internal keyway orspline corners allows you to run the pump without fear of vibration or shaft breakage.

-

316 SS Coupling is first interference fit, then pinned and keyed to the pump shaft. It slips over the keyed motorshaft and is locked in place with set screws.

-

The spring loaded mechanical shaft seal has a ceramic stationary face and carbon rotating face. Metal componentson the rotating half are 302 stainless steel and the elastomers are Buna N (nitrile) for cast iron models, andViton for stainless steel models. Because the seal is locked into position on the motor shaft by a separate stainlesssteel spacer, it is not disturbed when the rotating assembly is replaced. Maximum seal (inlet) pressure is 250PSI.

[/custom-features]

[custom-usage]

- Reverse Osmosis

- Deionization

- Car wash

- Washdown

- Booster Lift Station

- Industrial

- Agricultural

[/custom-usage]

-

Great filteration products

Worked highly efficiently!

ENGLISH arrow_drop_down

ENGLISH arrow_drop_down

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS