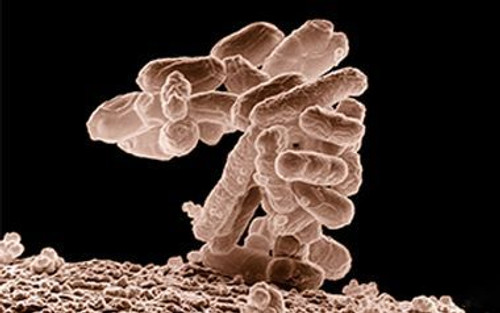

WHAT ARE COLIFORMS?

Coliforms are a bacterial family, which cover many types of bacteria that are usually present within the environment. They are found in high concentration in fecal matter of warm-blooded animals like dogs, deer and humans. Despite their high presence in the environment, most coliform bacteria do not cause illness on humans, but there are a few that can be infectious, mainly causing water-borne diseases like diarrhea. Coliform bacteria are easy to detect under laboratory conditions and are typically present in greater numbers than disease causing microbes. Their ability to last longer in aquatic or unfavorable environments, they tend to be used as determinants of possible contamination by harmful microbes. An absence of Coliform bacteria usually points to an absence of other pathogens. As a result of this, the presence of Coliform in water generally indicates that a contamination pathway exists between a possible source of bacteria (waste and sewage system, surface water) and the water supply. This means that potentially harmful bacteria could use this pathway to access the water in use.

REMOVAL METHODOLOGIES

When the test results come out, there are various paths that you could take to remove and prevent the presence of coliform bacteria. Depending on the level of analysis that you can get from the test, you will be aware of the type of bacteria as stated above and what type of treatment you should do.

- System Maintenance: Before we look at treatments, let us consider simple maintenance. Maintenance practices like extending a buried case above the ground ad sloping the ground away from the casing to prevent surface water from entering the well. You could also ensure that the top has a tight, sanitary well cap that prevents insects and animals from entering. If the tests reveal the presence of E.coli, check your septic system for any signs of leaks, blockages or any other malfunction especially around and leading to the well or spring.

- Shock Chlorination: Sometimes, coliform bacteria gets into the water system from a one-time or temporary contamination event such as heavy rainstorm, flood or installation of a new pump or other under surface system. Shock chlorination can be used to disinfect a well or spring by supplying a high concentration of chlorine to the water over a short period. This is like a one stop quick fix method of coliform removal.

To confirm the efficiency of the shock chlorination, retest the water for coliform within 2 weeks, and reconfirm after 2 months. If both tests return negative, then it is likely that it was a one-time contamination and has been cleared. If not, then you can move on to stricter treatment methodologies.

- Continuous Disinfection: Continuous chlorination introduces chlorine to the water through a feed system. The chlorine could either be liquid or solid. A filter is usually placed before the feed system to remove sediment from the water. The chlorine eliminates bacteria in the water but is also consumed by other impurities like iron and organic matter. Gauging the amount of chlorine to use should be dependent on the results of the tests regarding the presence of coliform and other impurities. It is important to note that excess should not be used as the residual chlorine after the disinfection affects the taste and color of the water. It is best to remove the chlorine after disinfection and before drinking.

The contact time of chlorine for continuous chlorination is usually 30 minutes for the elimination of the bacteria. As a result, standard pressure tanks are usually not large enough to cover for the time spent so large holding tanks are installed or it is run through a series of coiled pipes after being chlorinated. The chlorine systems must be functioning properly and regularly replenished to ensure efficiency.

HOW TO TREAT COLIFORM IN WATER

- Ultraviolet Light: The relatively easiest, most affordable and arguably the most effective way for a home owner to protect their water supply from coliform bacteria is to use a UV system. A UV system is a metal chamber that houses a UV lamp. Water flows through the chamber and is irradiated by huge amounts of UV radiation. This radiation destroys the bacteria and purifies the water.

It is advised that UV sterilization should not be used for water supplies where total coliform bacteria exceeds 1,000 colonies per 100ml or fecal coliform bacteria exceeds 100 colonies per 100ml. Also, the untreated water entering the unit must be completely clear and free from any suspended sediment or organic matter to allow the UV light gain direct access to the bacteria. Make sure to install the best water filter for coliform bacteria removal before the UV system can be efficient for this purpose.

- Ozonation and Boiling: Similar to chlorination, here ozone is injected into the water to kill the bacteria. Ozone is a gas that is produced using electricity. The advantage of ozonation is that it is used to treat water for multiple contaminants like bacteria, iron and manganese. The downside is that is more expensive than both chlorination and UV lighting system.

[custom-specifications]

IDENTIFICATION OF COLIFORM

The presence of coliform bacteria raises a common water quality problem in the United States. Coliform bacteria are mostly found in surface water sources like lakes, ponds, rivers and streams. They usually enter the surface water source when rainwater washes waste into the water system. Animals may defecate directly into small streams and they flow into larger streams and lakes, carrying the contaminated waste. Other times, they are discharged to natural waterways when human sewage treatment plants wrongly treat or disinfect sewage before discharging.

Apart from shallow water and wells, deep well contamination is also possible through water flow along the well casing especially if there is a crack, or if it is improperly built. It could also occur if the septic system weeping bed has been positioned too close to the well.

Specific types of coliform bacteria may be tested for in the identification of coliform bacteria. Sterile bottles must be used to collect water samples for coliform bacteria. An alternative to sterile bottles are bottles that have bacterial preservative. The bacteria is then cultured in a laboratory, and quantified. There are three groups of coliform bacteria and as well, there are three measurements of coliform bacteria.

- Total Coliform: These include many different species that live in different environs like soil, water, vegetation and in the digestive tract of warm blooded animals.

- Fecal Coliform: These are species of total bacteria that live in the intestines of warm-blooded animals.

- E. Coli: Full named Escherichia coli are specific to intestines of animals and humans.

[/custom-specifications]

[custom-features]

Recommended systems would be our:

- Commercial Reverse Osmosis System RO-200 Series

- Commercial Brackish Water Reverse Osmosis System RO-300 Series

- Industrial Reverse Osmosis System RO-400 Series

- Industrial Brackish Water Reverse Osmosis System RO-500 Series

- Industrial UV Sterilizer UVI Series

- Commercial UV Sterilizer UVC Series

[/custom-features]

[custom-usage]

Boiling also provides other advantages in purifying water from coliform, especially drinking water that is needed in relatively small quantities. Water boiled for a minute kills all bacteria. The converse side is that this method is very expensive and requires a lot of energy.

To ensure that there are no reoccurrences after the removal of coliforms, both the removal procedures and the system maintenance should be used. This ensures that there will be no room for such bacteria to enter into the water supply in the future and ensure health of all involved.

Most of these treatment systems are complex and experts should be called to install them. Also they should be purchased from recognized water treatment companies.

[/custom-usage]

[custom-documents]

[/custom-documents]

-

Great information!

Content was exceptional

- Related Project1:

- https://pureaqua.com/industrial-ultraviolet-sterilizer-4-x-500-gpm-usa/

- Related Project2:

- https://pureaqua.com/ultraviolet-industrial-sterilizer-4x-800-gpm-aruba/

- Related Project3:

- https://pureaqua.com/ultraviolet-sterilizer-550-gpm-jordan/

- Related Project4:

- https://pureaqua.com/ultraviolet-industrial-sterilizer-670-gpm-ecuador/

ENGLISH arrow_drop_down

ENGLISH arrow_drop_down

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS