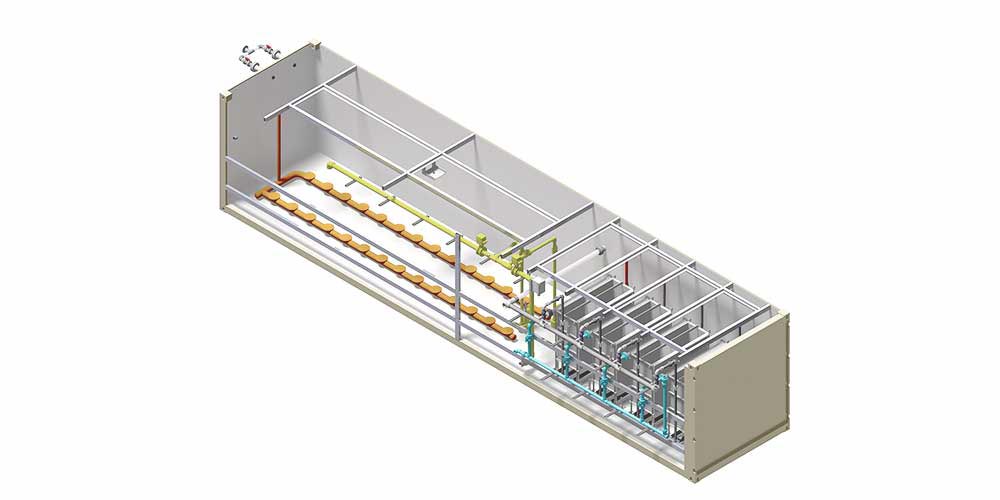

MBR-C Process Description

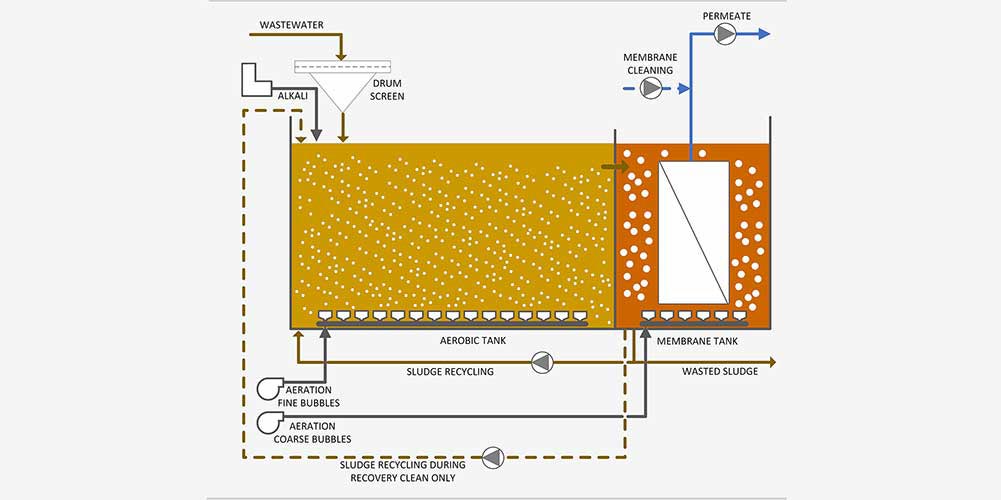

MBR-C is a containerized MBR which utilizes hollow fiber (HF) ultrafiltration (UF) membranes with nominal pore size of 0.04 µm. In a typical MBR-C system, feed water passes through a drum screen to mitigate suspended solids and protect membranes’ surface. Water is then transferred to a bioreactor where microorganisms decompose organic content to mineral constituents of CO2, H2O, and inorganic nitrogen products at ambient temperature. Thereafter, water overflows to membrane tank(s), where UF membranes achieve complete retention of bacterial flocs, suspended solids, small colloids, and viruses.

Submerged HF Membrane Technology

MBR-C utilizes submerged membrane module (SMM) products featuring the best-in-class thermally induced phase separation (TIPS) polyvinylidene difluoride (PVDF), innovative modules, and skid designs to provide the most compact, simple, and reliable solution. SMM products are typically implemented in MBR applications treating municipal and industrial wastewaters. They are designed to effectively meet the needs of customers designing a new facility or replacing existing skids of any other manufacturer.

Containerized Membrane Bioreactor (MBR-C) Process Flow Diagram

Advantages of MBR-C

MBR-C provides numerous advantages over all known biological treatment processes presently in use:

- Enhanced Membrane Technology

- TIPS spinning method → high tensile strength and long lifetime

- PVDF membrane material → higher chlorine tolerance compared to other membrane materials (e.g., PES)

- High packing density → fewer skids, smaller footprint, and higher productivity

- Patented air scouring technologies → low energy consumption

- Extreme caustic and oxidant tolerance → suitable for challenging applications

- Dense crystalline and monolithic structure → direct integrity testing capability

- Economy

- Integration of bio-treatment and membrane filtration eliminates the need for sedimentation tank and allows for compact design and installation.

- Minimal pumping requirements reduces equipment and operational costs.

- Lower sludge production rate, due to higher sludge age (i.e., SRT), compared to conventional activated sludge processes results in savings on disposal expenses.

- Smaller Aeration Tank and Footprint

- High mixed liquor suspended solids (MLSS) concentration and volumetric loading rate translate into compact footprint.

- Water of superior quality

- Membranes are capable of retaining activated sludge at high MLSS concentrations, leading to more effective BOD and nitrogen removal.

- UF membranes are capable of removing small colloids and viruses in addition to suspended solids and bacterial flocs.

- Ease of operation and maintenance

- MBR-C can operate largely unattended with the exception of occasional routine performance checks and maintenance of mechanical components.

- Segregated bioreactor and membrane tanks will allow for easy operation and maintenance.

Typical performance for sewage wastewater applications

|

Parameter |

Feed Water Quality |

Expected Permeate Quality |

|

pH |

6.5-7.5 S.U. |

6.5-7.5 S.U. |

|

Alkalinity (as CaCO3) |

125 mg/L |

≥100 mg/L |

|

Temperature Range |

20-30°C |

20-30°C |

|

TSS |

200 |

<5 mg/L |

|

Biochemical Oxygen Demand (BOD) |

250 |

< 10 mg/L |

|

Chemical Oxygen Demand (COD) |

400 |

<50 mg/L |

|

Ammonium-Nitrogen (NH4) |

30 |

<2 mg/L |

|

*Values presented here do not represent guarantees. |

||

[custom-specifications]

|

|

Flow Rate |

|

Membranes |

|

|

||

|

gpd |

m3/d |

# of Skids |

# of Modules |

||||

|

MBR-C-13.2K-06 |

13,211 |

50 |

265 |

2 |

3 |

316SS |

1 × 20' |

|

MBR-C-26.4K-10 |

26,421 |

100 |

529 |

2 |

5 |

316SS |

1 × 40' |

|

MBR-C-39.6K-16 |

39,631 |

150 |

793 |

2 |

8 |

316SS |

1 × 40' |

|

MBR-C-50.2K-20 |

50,199 |

190 |

1004 |

2 |

10 |

316SS |

1 × 40' |

[/custom-specifications]

[custom-features]

|

Standard Features |

Operating conditions |

Available Options |

|

|

|

[custom-usage]

- Municipal wastewater Treatment

- Residential and commercial wastewater treatment (e.g., camps, hospitals, office complexes, golf courses, restaurants, and car washes)

- Water reclamation (e.g., irrigation of gardens or agricultural fields)

- Pre-treatment for Reverse Osmosis (RO) system

- Industrial wastewater treatment

[/custom-usage]

Here at Pure Aqua, Inc., we engineer and build all of our water treatment systems in-house.

Our turn-key water treatment systems are all pre-engineered using the latest CAD technology available.

This enables our teams to build and deliver treatment systems to our customers with quick turnaround times.

Many of our customers require custom engineered systems. These are typically built around similar core systems and thus allowing for improved turnaround times, even for one-off designs.

-

The system runs quietly and we have no quality issues

We bought a MBR-C system and the efficiency in treating wastewater is first-rate!

-

Great system

It solved our wastewater treatment problem efficiently. Thanks!

-

Very supportive

It took us sometime to figure out what system do we need to solve our sewage treatment problem, but Pure Aqua engineers are very helpful and supportive. they made it easy on us. The system is running now for over a month with no issues at all. Thanks!

-

Competitive price!

We recommend contacting Pure Aqua if you are still shopping around for the best price...Pure Aqua offers reasonable pricing even with complicated systems like this.

-

Problem solved!

Your system solved our water treatment problem here in our city. Thanks!

-

Very energy efficient system!

It was hard for us to find a manufacturer that can engineer one like this to run on a solar power. Pure Aqua systems' engineering is very efficient.

-

The best containerized sewage treatment system.

I believe this is one of the best containerized sewage treatment system.

-

Awesome engineering.

Pure Aqua really has a very clean design even with complicated systems like this.

- 360view:

- https://pureaqua.com/content/360Views/Waste Water Treatment Container.html

- 360image:

- https://cdn11.bigcommerce.com/s-1x0ys7yqwf/product_images/uploaded_images/360view-wireframe-small.jpg

ENGLISH arrow_drop_down

ENGLISH arrow_drop_down

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS