Advanced Ultrafiltration (UF) Systems

Pure Aqua, Inc. engineers and manufactures the most advanced Ultrafiltration (UF) systems for water treatment purposes that fit the needs of different industries and application such as chemical and pharmaceutical manufacturing, food and beverage processing, and wastewater treatment…etc.

Other important applications within the water treatment industry that require the ultrafiltration systems for the improvement of their own processes can be seen in the following:

- RO Pretreatment

- Grey Water Treatment

- Water Recycling

- Water Reclamation

- Drinking Water Treatment

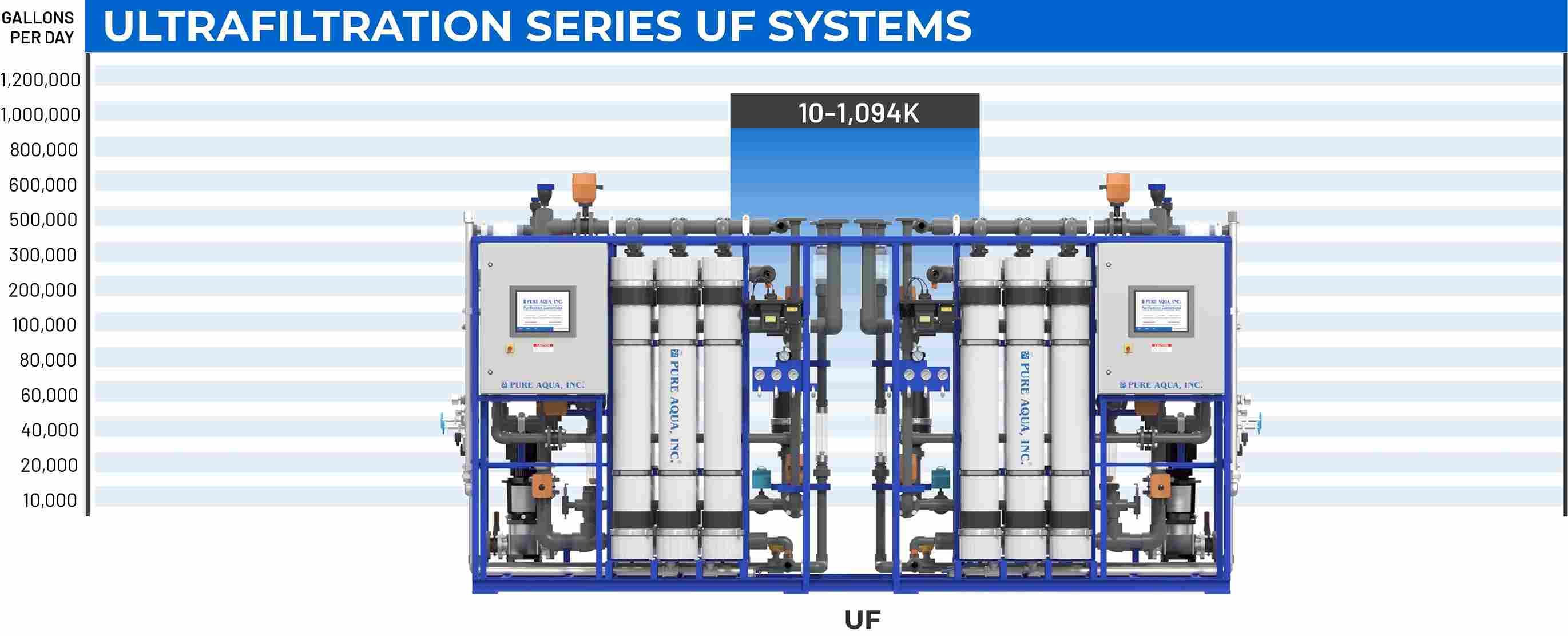

Daily Capacity Range:

10,000 to 1,037,000 GPD

(38 to 3,928 M³/day)

- Turbidity: up to 300 ppm

- UF modules with Different Flux Rates

- TSS: up to 100 mg/l

Daily Capacity Range:

Flow Rate Varies

- Turbidity: up to 300 ppm

- UF modules with Different Flux Rates

- TSS: up to 100 mg/l

Pure Aqua has over 20 years of experience as a global supplier of ultrafiltration systems that are designed to reliably remove suspended solids, turbidity, bacteria, pathogens and viruses from water. These systems are made to be economical, compact, and capable of allowing decreased plugging, and greater solids loading. The UF membranes ensure maximum filtration performance with high flux, including the system's resistance to chemicals and high tolerance to changing temperatures.

How Ultrafiltration (UF) Systems Work?

Ultrafiltration (UF) systems have diverse membrane filtrations where hydrostatic pressure pushes solvents against a very fine membrane. They block suspended particulates and solids that are large while water and solutes with a lower molecular weight are allowed to flow through the membrane.

Industry and research employ this separation process for purifying and concentrating macromolecular (103 - 106 Da) solutions, which are usually protein solutions. Ultrafiltration is similar to microfiltration, nanofiltration or gas separation, except it differs in the molecule sizes it blocks.

To meet critical discharge criteria, ultrafiltration systems remove the need for clarifiers and multimedia water filtration. Effective ultrafiltration systems use membranes that can be immersed, back-flushable, and air scoured. Spiral wound UF/MF membranes offer excellent performance for the clarification of process water and waste water.

Ultrafiltration (UF) Systems Advantages

Ultrafiltration (UF) membranes systems are more reliable than a conventional multi-media filter, which removed approximately 10 micron or larger of matter, where an ultrafiltration membrane pore size ranges from 0.01 to 0.10 micron. In addition to superior turbidity removal, UF membranes efficiently remove bacteria and most viruses.

- Superior filtration performance with high flux

- Very small nominal pore diameter (0.03 µm)

- Efficiently removes bacteria and viruses

- Occasionally back washed and air scoured to boost performance and removing the fouling layer to extend operating life

- Low fouling membrane modules

- UF Outside-In or Inside-Out Configuration permits reduced plugging and higher solids loading

- Basic, vertical, modular design permits low cost, compact systems

- Effective membrane cleaning has a high chemical resistance and temperature tolerance

What is ultrafiltration in water treatment?

Ultrafiltration systems utilize hollow membrane fibers to eliminate suspended solids, bacteria, viruses, and pathogens from the feed water. Pumps send the treated water through microscopic pores, which act as a physical barrier that only allows filtrates to pass through them. Ultrafiltration strainers are used next to remove solids such as weeds and plastics from the filtered water before it enters the UF system. Ultrafiltration plants have been extremely useful in water and wastewater treatment by continuously providing excellent results. After UF treatment, the water can be sent to a reverse osmosis system for further purification or can be used supplied for immediate public usage.

What is Ultrafiltration (UF) Plant and its importance?

Most regions around the world utilize ultrafiltration plants to maintain sufficient preservation of clean water for public consumption. The water filtration efficiency achieved by UF systems are around 250 times greater than conventional media filtration systems. These plants are also very suitable to many industries that require ultra pure water pushed out from these factories. The ultrafiltration membranes used in these plants are enforced to lower turbidity, or utilize as pretreatment to maintain the effectiveness of your reverse osmosis membrane. These plants are generally considered to be of low cost, easy to operate, carry no contaminate residue, and have considerably high recovery ratio.

ENGLISH arrow_drop_down

ENGLISH arrow_drop_down

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS