RO Membrane Systems

The use of the reverse osmosis process has been dated back to the 1970's when certain towns in the United States were depending on water filtration to remove harmful properties from their drinking water. Once households began implementing this process in the form of small water filtration systems, then larger units began being built for commercial businesses and industrial plants. As local regulations became introduced for the purposes of ensuring certain policy standards, reverse osmosis systems increasingly improved in safety and production of high quality water with lower amounts of energy required to operate. The benefits of these advancements in RO technology has helped to provide pure and potable water that is free of unwanted chemicals, toxins, and other impurities which increases the standard of living of communities and contributes to a healthy lifestyle. Check out our fine selection of reverse osmosis systems, which range from brackish to seawater (commercial & industrial), to our membrane systems that consist of nanofiltration, ultrafiltration, and membrane cleaning systems that serve as fantastic and often very necessary pretreatment units.

Daily Capacity Range:

600 to 32,000 GPD

(2 to 121 M³/day)

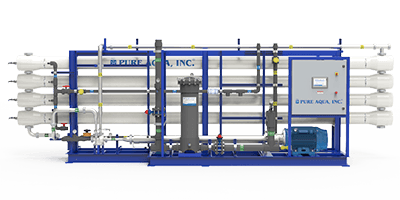

Daily Capacity Range:

28,800 to 2M GPD

(109 to 7,570 M³/day)

Daily Capacity Range:

380 to 10,000 GPD

(1.4 to 38 M³/day)

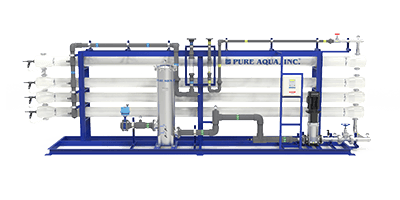

Daily Capacity Range:

8,000 to 660,000 GPD

(30 to 2,500 M³/day)

Daily Capacity Range:

13,000 to 32,000 GPD

(50 to 121 M³/day)

Daily Capacity Range:

190,000 to 855,000 GPD

(719 to 3,236 M³/day)

OFF-GRID UF Systems

Flow Rate Varies

Daily Capacity Range:

10,000 to 1,037,000 GPD

(38 to 3,928 M³/day)

Up to 3 Pressure Vessels

Flowrates: 8 to 30 GPM

(1.8 to 6.8 M³/hr)

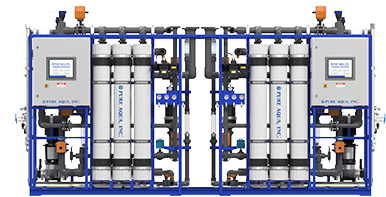

Up to 6 Pressure Vessels

Flowrates: 40 to 210 GPM

(9 to 48 M³/hr)

Pure Aqua has over 20 years of experience as a world-wide supplier of water treatment systems for a wide range of applications. From reverse osmosis systems to nanofiltration, ultrafiltration, and membrane cleaning systems, these units are designed to remove various impurities and produce ultra clean water.

Pure Aqua designs and manufactures the most advanced reverse osmosis and membrane systems in the market to meet all industry needs and applications.

We pride ourselves on our reverse osmosis/water treatment systems. It’s these very systems that give us a reputation for quality and efficiency above all others in the industry. Reverse Osmosis (RO) technology, also known as hyper filtration, is used in our municipal, commercial, and industrial water treatment systems to purify water by removing salts, contaminants, heavy metals, and other impurities.

As the pinnacle of recovery rates, rejection, and energy efficiency, it is reverse osmosis systems that make the water treatment industry effective.

We have multiple pre-engineered models to choose from, as well as custom treatment systems from smaller containerized systems to full water treatment plants all to meet your specific water purification needs.

Learn more about what is reverse osmosis

How does reverse osmosis work?

Reverse osmosis systems work by applying a high pressure pump to a concentrated solution of unfiltered water, which can be in the form of seawater, brackish, or tap water. The system forces the water through a semipermeable membrane, leaving virtually all of the dissolved salts and other substances behind. The type of water you’re looking to purify using reverse osmosis systems will determine which pump will be needed to use in order to see effective results. Seawater requires larger and higher pressure pumps compared to brackish or tap water since it has a higher content of total dissolved solids (TDS). Pretreatment is necessary when working with reverse osmosis systems to protect the membranes from fouling and failing prematurely. This degradation of the reverse osmosis membrane occurs due to a build up of foulants such as silica, iron, manganese, calcium carbonate, dead and living organisms, and magnesium carbonate.

Does reverse osmosis remove fluoride?

Yes, reverse osmosis systems are extremely effective at removing most impurities in water, and fluoride is one of them. However, the efficiency at which reverse osmosis filters fluoride from water relies on its capacity to block fluoride molecules from coursing through its minuscule openings. Ultimately, the size of the openings within the reverse osmosis membrane will be the deciding factor on what passes through it. Generally, the size of fluoride molecules are too enormous to course through even the smallest openings of reverse osmosis systems.

Does reverse osmosis remove lead?

Reverse osmosis systems are one of the most preferred water filtration systems when it comes to lead removal. RO systems have the ability to eradicate up to 99% of the lead (and other heavy metals) in water that passes through its membranes. This is a sufficient rate to allow for consumable water for humans, animals, and plants.

How do reverse osmosis membranes work?

Reverse osmosis membranes can be considered as the core of the reverse osmosis systems. These elements are responsible for the actual filtration process within these systems and therefore must be ensured to be of the highest quality. Many RO operators choose to utilize lower quality membranes for the purposes of saving operational costs. While this decision works in saving immediate plant expenses, the overall productivity and long-term costs is substantially effected. The difference in performance among high quality and low quality reverse osmosis membranes is stark, with the former producing far more effective filtration results.

Greater rejection percentage, energy saving, and fouling resistance are the three primary benefits bestowed upon RO operators who make the effort of acquiring and utilizing superior membrane elements. Quality reverse osmosis membranes can be attained from major brands such as Dow Filmtec, Hydranautics, and Toray.

We have manufactured thousands of reverse osmosis systems that are operating worldwide, producing millions of gallons of water daily. If you have any water treatment needs, please give us a call at 714-432-9996 and we will be happy to provide you with a quote or any information you may need.

ENGLISH arrow_drop_down

ENGLISH arrow_drop_down

ESPAÑOL

ESPAÑOL ???????

??????? PORTUGUÉS

PORTUGUÉS FRANÇAIS

FRANÇAIS